Pad Printing or Screen Printing: Which One is Right for You?

It is an important decision for any business to decide on the right printing method. Whether you choose pad printing or screen printing, the results can be greatly affected. It won’t be wrong to say each method brings its own set of benefits and demerits. Once you are able to understand pad printing and screen printing techniques, you can make better decisions in light of your specific needs.

What is Pad Printing?

Pad printing can be described as a printing technique where ink is transferred from a silicone pad onto various services. This classifies pad printing as a versatile technique that is mostly used for printing on irregular, uneven, or curved surfaces. Different industries like automotive, promotional products, and medical devices bring this method in hand where their priority is fine detail and precision.

Pros of Pad Printing

Diversity: Perfect for printing on diverse surfaces like plastics, metals, glass, and ceramics.

Accuracy: Ideal for small, intricate designs and fine text.

Speed: Effective for large-scale manufacturing runs.

Color range: Capable of producing multi-colored designs with flawless alignment.

Cons of Pad Printing

Setup purchase: The purchase of pads and clichés (printing plates) might make the initial setup costly.

Surface Restrictions: Compared to other techniques, it is less successful on flat surfaces.

Ink Thickness: Not all applications, particularly those that demand high durability, may be appropriate for thinner ink layers.

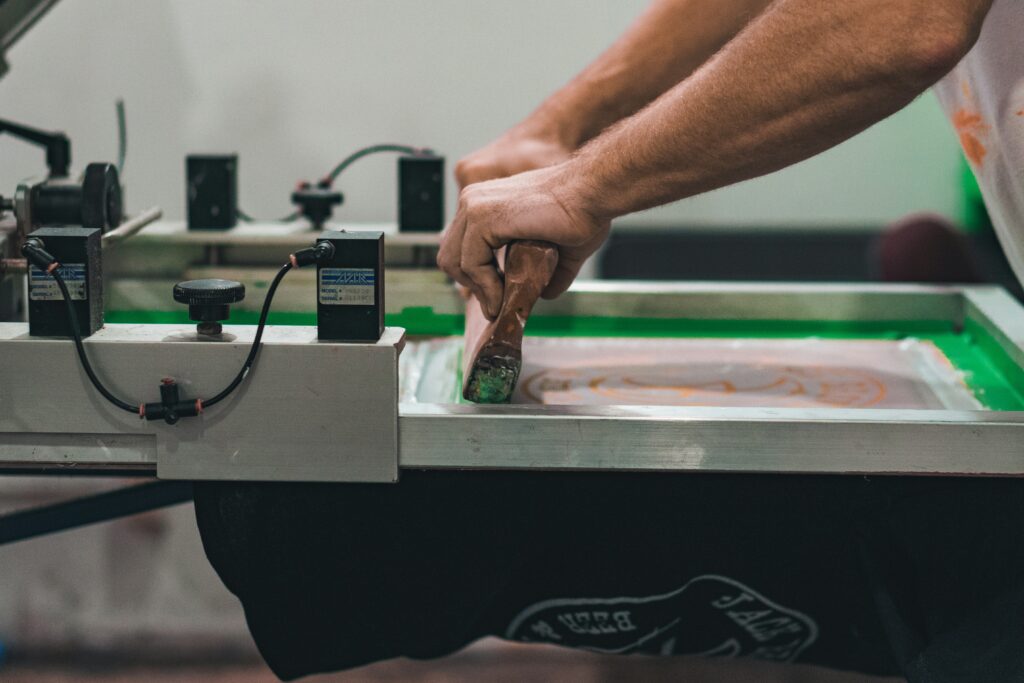

What is Screen Printing?

Screen printing which is also known as silk screening is a process of pushing ink onto a surface through a mesh stencil. This method is mostly used for printing on ceramics, wood, glass, etc. What makes screen printing favorable is how it makes it possible to produce vibrant and bright colors. This technique allows for thick layers of ink and creates durable prints.

Pros of Screen Printing

Durability: Creates thick, long-lasting ink layers that hold up to frequent washings and extensive use.

Bright Colours: Able to produce high opacity, eye-catching, vibrant graphics.

Versatility: Printable on a variety of substrates and surfaces.

Cons of screen printing

Setup Time: longer setup times as a result of the stencil and screen preparation.

Detail Limitation: Compared to pad printing, it is less effective for very fine or intricate work.

Wastage: Compared to pad printing, it can generate more trash and use more ink.

Limited Runs: Because of setup costs, small manufacturing runs are less economical.

Which One is Right for Your Business?

Surface and Shape: Pad printing is ideal for products with irregular shapes or three-dimensional surfaces, making it perfect for items like promotional products, automotive parts, and medical devices. On the other hand, screen printing excels on flat surfaces and larger areas, such as t-shirts, posters, and signage.

Detail and Precision: If your design requires fine details and small text, pad printing offers superior accuracy and clean lines. This makes it a great choice for intricate logos and detailed artwork. Screen printing, however, is better suited for bold, vibrant designs, where thick layers of ink create striking, eye-catching visuals.

Environmental Factors: In today’s world businesses have to be concerned for the environment as well. In respect to this, pad printing stands out for its lower ink usage and minimal waste production, hence making it a more environmentally friendly option. Although screen printing is effective, it uses more ink and produces more waste, making it less attractive to sustainability concerns.

Cost Considerations: When comparing cost-effective printing methods, pad printing often reduces costs over time. Pad printing makes it possible to reduce costs over time. Basically, ad printing generally offers lower material costs due to its efficient ink usage, unlike screen printing. Even if the initial setup might be higher, the long-term savings are significant, especially for high-volume production runs.

The decision between pad printing and screen printing ultimately narrows down according to the specific requirements of any company. You may make an informed choice if you are aware of the differences between each approach and take your own demands into respect. To get the greatest results for your company, whether you choose pad printing or screen printing, make sure it fits your budget, production objectives, and environmental concerns.

Specializing in pad printing, Precision Textiles offers high-quality, detailed printing solutions tailored to your unique needs. Whether you require intricate designs on irregular surfaces or precise multi-colored prints, their advanced pad printing services ensure exceptional results for your projects.